Choosing roofing shoes doesn’t feel like a big decision… until it is. Until a roof that felt fine an hour ago turns slick, granules shift under your feet, the morning dew hangs around longer than expected, and that one miscalculated step slides six inches farther than it should.

Roofing is already one of the most dangerous trades in construction. Footwear is one of the few variables you actually control. And most roofers don’t think about it until something goes wrong.

If you want to reduce slips, prevent injuries, and keep your crew productive, this guide breaks down how to choose roofing shoes the right way, not by brand hype, but by function, risk, and real job conditions. So, get non-slip roofing shoes to inspect tiles fearlessly & confidently!

Why Slips Happen on Roofs (Even When You’re Careful)

A slick roof doesn’t care how experienced you are. It doesn’t care how confident you felt stepping off the ladder, nor does it care that you’ve walked this pitch a hundred times. This traction changes constantly because:

- Granules act like ball bearings

- Dust builds up during tear-offs

- Heat softens shingles

- Morning dew lingers in shaded areas

- Metal panels amplify every mistake

Most slips aren’t dramatic. They’re subtle: a half-step slide, a weight shift, or a delayed reaction. That’s how injuries start and snowball into a menacing problem for company owners. Roofers consistently experience some of the highest fall rates in construction. Falls remain the leading cause of death in the industry, accounting for nearly 38% of construction fatalities.

And footwear plays a bigger role than most crews admit. Shoes affect how you move, how fast you work, and how confident you feel on a slope. When traction feels unreliable, roofers rush ladders, lean wrong, and take shortcuts. That’s not a discipline problem, but a gear problem.

The companies that reduce incidents don’t rely on toughness. They rely on systems: clear job planning, consistent safety expectations, and documentation that keeps crews from scrambling.

That level of organization is exactly why many growing roofing companies lean on platforms like ProLine to keep jobs, crews, and communication aligned when things get busy. Use Proline to boost your roofing sales with tried-and-trusted methods without losing your me-time.

The Real Cost of a Slip: Injuries, Downtime, and Liability

A slip doesn’t just hurt the roofer; it hurts the business. Workplace injuries cost U.S. employers over $170 billion annually in medical expenses, lost productivity, and insurance costs. That’s why for roofing companies, that shows up fast:

- Lost workdays

- Delayed jobs

- Workers’ comp claims

- Higher premiums

- Crew morale hits

One injury can stall production for weeks… and in peak season, downtime is expensive.

This is where smart owners zoom out. They stop treating slips as bad luck and start treating them as process failures. When you can see where jobs rush, where conditions change, and where communication breaks down, patterns appear.

Tools like ProLine help owners track jobs, timelines, and crew assignments, so safety decisions aren’t left to memory or guesswork. Let’s make it easier to choose roofing shoes…

The 5 Non-Negotiable Features Roofing Shoes Must Have

1. Traction Built for Roofing Surfaces

Not all traction is created equal. Most work boots are designed for dirt, concrete, and flat ground. Roofing shoes live in a different world, so they need to grip surfaces that constantly change under your feet:

- Asphalt shingles

- Loose granules

- Dusty tear-offs

- Occasional moisture

- Heat-softened materials

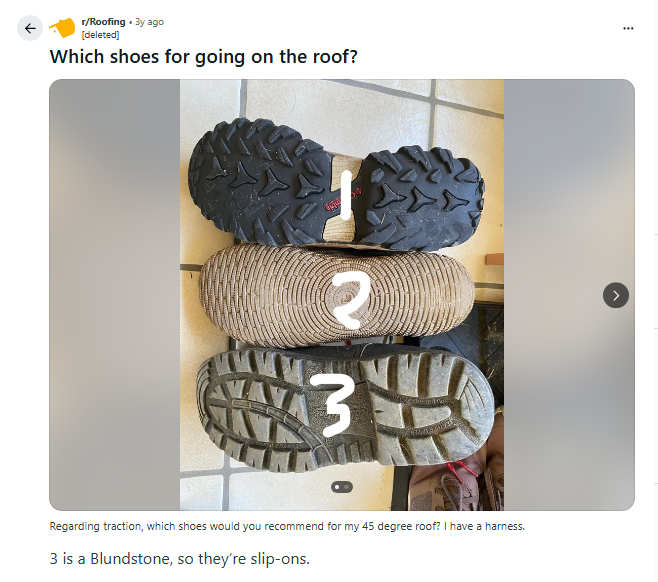

This is where many roofers get misled. Flat, hard soles slide, aggressive lugs don’t help on shingles, and “tough” doesn’t mean “grippy.” You need to ignore these misconceptions to save the lives of your workers on tough jobs. It’s time you changed your mind about roofing shoes.

Roofing traction works through surface contact, not bite. The sole needs to press into the roof and maximize friction. That’s why softer rubber compounds almost always outperform harder soles on slopes, especially on finished asphalt roofs.

The danger is inconsistency when one roofer grips fine, while another slips on the same pitch.

Companies that reduce injuries standardize expectations… including footwear. When safety standards are documented and communicated clearly across crews, variability drops; as a result, everyone knows what’s acceptable. Everyone shows up prepared.

2. Sole Softness vs Durability (You Can’t Ignore the Trade-Off)

This is the trade-off every roofer tries to avoid: softer soles grip better and harder soles last longer. You don’t get both forever.

Soft soles compress into shingles, creating friction and control. But they wear fast, especially on tear-offs, debris, and ladders; on the other hand, hard soles survive abuse but lose grip where it matters most. The mistake is pretending one shoe solves everything.

Remember, when you choose roofing shoes, there’s no one-size-fits-all approach to this problem.

That’s how roofers end up slipping on finished roofs or burning through shoes faster than expected. The smarter approach is matching footwear to job type instead of forcing one boot to cover every situation.

This is easier when job details aren’t scattered across texts and memory. When scopes, surfaces, and crew assignments are visible in one place, footwear decisions become proactive instead of reactive. Your crews show up equipped and not guessing.

3. Ankle Support Without Killing Mobility

Science tells us that more ankle support feels safer (sometimes it is, and sometimes it isn’t).

Stiff boots limit foot articulation. On steep slopes, that matters. When your ankle can’t adjust naturally to pitch changes, balance suffers, and your body compensates higher up the chain (knees, hips, & back). That’s when slips happen (i.e., when you least expect them).

Ankle support helps on ladders, ground work, and uneven terrain. But too much support on pitched roofs can work against you, especially during long days when fatigue sets in.

This is why experienced roofers rotate footwear based on the work they’re doing that day. They don’t force one boot to handle everything. They choose mobility or support intentionally.

It’s not about comfort. It’s about control.

4. Weight and Fatigue Matter More Than You Think

Heavy footwear accelerates fatigue… and fatigue changes everything.

- Your reaction time slows

- Balance corrections lag

- Mistakes increase

Most slips don’t happen in the first hour; instead, they happen late in the day, when your legs are tired, and your focus begins to fade.

NIOSH research consistently shows fatigue is a major contributor to workplace injuries in physically demanding jobs.

Lightweight shoes don’t just feel better; they help roofers stay sharp longer. Less weight means less strain with every step. Over hundreds of steps on a slope, that adds up.

This is also where operational decisions matter. When your crews are rushed, overbooked, or juggling unclear schedules, fatigue compounds fast. Injuries spike under pressure.

That’s why workload visibility and communication matter just as much as gear. When jobs are planned realistically and workloads are balanced, safety doesn’t erode under stress. ProLine helps companies see the full picture so crews aren’t pushed into risky conditions just to keep up.

5. Surface Awareness (“Roof Feel”)

Roof feel matters more than most people admit. Shoes that isolate your foot too much reduce feedback. You feel the slope later. You react more slowly. Balance adjustments lag behind movement. Roofers rely on micro-feedback that comes in the form of:

- Pressure changes

- Pitch angles

- Texture shifts

That information keeps you upright.

When your shoes dull that feedback, surprises increase… and surprises on a roof are never short of dangerous.

This is one reason veteran roofers adjust footwear by task. They choose shoes that let them feel the roof when precision matters. They neither guess nor wing it.

It’s also why structured job planning beats last-minute scrambling. When crews know what surface they’re walking before they arrive, footwear becomes a decision, not a gamble.

Why One Shoe Doesn’t Work for Every Roofer

Roofing isn’t one environment; treating it like one is where problems start.

- Tear-offs punish footwear fast

- Inspections demand mobility

- Steep installs require maximum grip

- Metal roofs change everything

Trying to force one shoe into every role creates compromise. And compromise increases risk.

The most consistent crews don’t guess. They rotate footwear intentionally based on the job, the surface, and the role. That takes awareness, communication, and planning. When job types, notes, and schedules live in one place, those decisions happen naturally instead of reactively.

Different roles need different priorities.

- Installers need traction first. Fatigue reduction matters. Task-specific footwear makes a real difference when slope and surface change throughout the day. Rotating shoes isn’t a luxury; it’s how installers stay sharp and upright.

- Sales reps and inspectors need lightweight mobility. Ladder comfort. Confidence in finished roofs. Steel toes don’t help here. Balance and comfort do, especially during long inspection days.

- Owners and managers need versatility. Professional appearance. Safety optics. You’re on roofs occasionally, not all day. Choosing the right footwear sends a signal. When crews see leadership taking safety seriously, standards stick.

This is where myths cause damage.

- “Heavier boots are safer.” They’re not, since weight doesn’t equal traction.

- “Grip is grip.” It isn’t. Surface-specific traction matters.

- “If it worked last year, it still works.” Your shoes wear out quietly.

- “Carefulness is enough.” Data says otherwise; construction injuries rise when safety decisions rely on habit instead of evaluation.

Slips Aren’t Bad Luck. They’re Preventable.

Footwear is one piece of your entire system. Communication is another. When job details, crew assignments, photos, and follow-ups all live in one place, safety decisions stop being reactive. Crews aren’t rushing. Owners aren’t guessing. Small issues get handled before they turn into problems. That’s where platforms like ProLine fit in quietly, helping roofing companies stay organized, communicate clearly, and keep jobs moving without chaos.

If you want support that makes the early days smoother and scaling easier, it helps to have one tool that keeps your leads, jobs, communication, and follow-up on track. So, book a demo with ProLine today and see how a communication-first CRM helps new owners close more jobs, stay organized, and make it home for dinner. We streamline lead generation.

FAQs

What shoes reduce slipping the most on asphalt roofs?

Shoes with softer rubber compounds designed for roofing surfaces typically provide better grip than general construction boots.

Are roofing shoes required by OSHA?

OSHA requires employers to address slip hazards, but footwear selection falls under the employer’s safety responsibility.

How often should roofing shoes be replaced?

Replacement ranges from weeks to months, depending on usage, roof surfaces, and visible wear.

Are boots or shoes better for steep roofs?

It depends. Flexibility and traction often matter more than ankle height on pitched surfaces.